Source:Industry News Release time:2022-03-10 Clicks:0 Popular:Reduction motor manufacturer

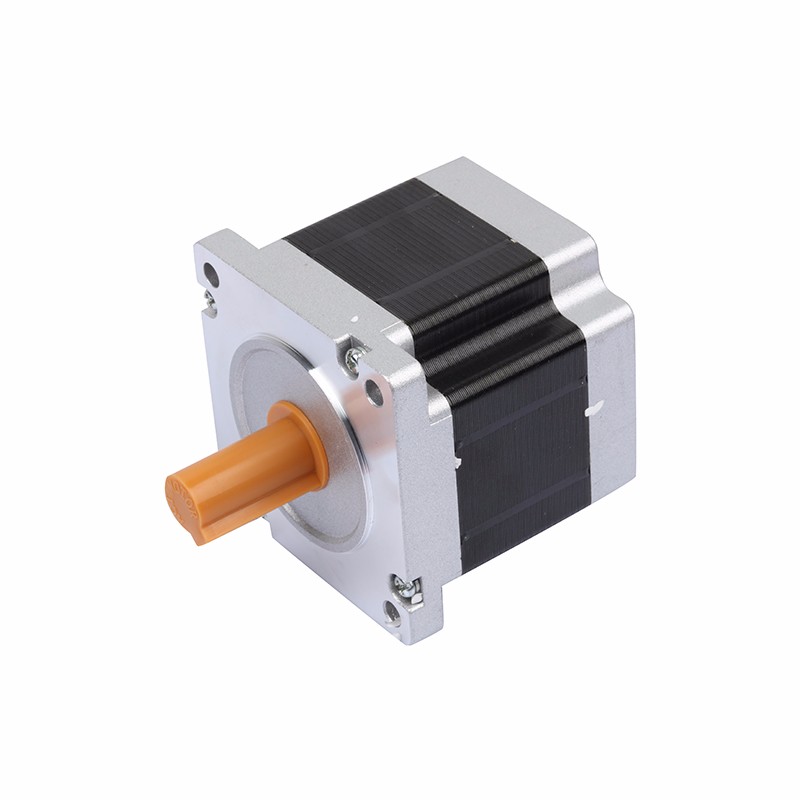

Principle of stepper motor: Stepper motor is an open-loop control component that converts electrical pulse signals into angular displacement or linear displacement. Under non-overload conditions, the motor's speed and stop position only depend on the frequency and number of pulses of the pulse signal and are not affected by load changes. That is, a pulse signal is added to the motor and the motor rotates by a step angle.

The existence of this linear relationship, coupled with the fact that stepper motors only have period errors and no cumulative errors, make it very simple to use stepper motors to control speed, position and other control areas. Although stepper motors have been widely used, stepper motors are different from ordinary DC motors. AC motors are commonly used. It must be used by a control system composed of double-ring pulse signals, power drive circuits, etc. Therefore, it is not easy to use stepper motors well. It involves many professional knowledge such as mechanics, electrical machinery, electronics and computers.

Briefly describe the working principle of screw stepper motor

A screw stepper motor or linear stepper motor is rotated by a magnetic rotor core through the interaction with the pulsed electromagnetic field generated by the stator. Screw stepper motors convert rotational motion into linear motion inside the motor.

Recommended reading

How to clean the internal parts of the right angle planetary reducer

Related Information

CGH-090L1-10-P1

2020-12-21Stepper motor

2021-04-14CGF-042L1-8-P2

2020-12-21Rod motor

2021-04-17Planetary reducer

2020-12-21Planetary reducer

2020-12-21CGX115

2021-01-13CGXZ042

2021-01-13CGXZ060

2021-01-13Planetary reducer

2021-04-15Small reduction motor

2020-12-21CGXZ085

2021-01-13Stepper motor

2021-04-14Stepper motor

2021-04-14CGXZ060

2021-01-13CGXZ115

2021-01-13CGXZK115

2021-01-13Stepper motor

2021-04-14