Source:Industry News Release time:2022-10-08 Clicks:0 Popular:Reduction motor manufacturer

Routine maintenance of disc planetary reducer:

1. When using a reducer for a disk planetary reducer, first check whether the matching motor and load standards are consistent with the data and information listed in the instruction manual.

2. The reducer should be cleaned before use and filled with HJ-40 or N200 oil according to the requirements of this instruction manual. The dipstick should be observed throughout the application. The remaining oil volume should not be more or less than the oil volume.

3. When installing the pulley, sprocket chain, transmission gear and coupling on the disc planetary reducer shaft. During installation, the installation site should be heated to 100℃~150℃. Do not hit with a hammer during installation, and sprinkle water to cool down to prevent the skeleton seal from burning out and the bearing end cover from being damaged.

4. When selecting the coupling transmission system, ensure that the non-parallelism of its pivot axis does not exceed 0.075mm. When the output shaft is connected to operating mechanical equipment, the use of rigid couplings is highly recommended. At the same time, check and adjust the tightening status of each position.

5. After the disk planetary reducer is installed, it should be operated at full load. After checking that all components and organizations are functioning properly, they can work under load. When operating at full load, the temperature rise of the planetary reducer should not exceed 40°C, but the maximum temperature should be less than 60°C. If you find that the temperature rise is too high or the sound is abnormal, you should stop the machine to check and analyze the cause, and then use it after the fault is found.

Recommended reading

What is the purpose of a geared motor and how does it work?

Stepper motor manufacturers introduce the main parameters and characteristics of stepper motors

Related Information

Stepper motor

2020-12-21Stepper motor

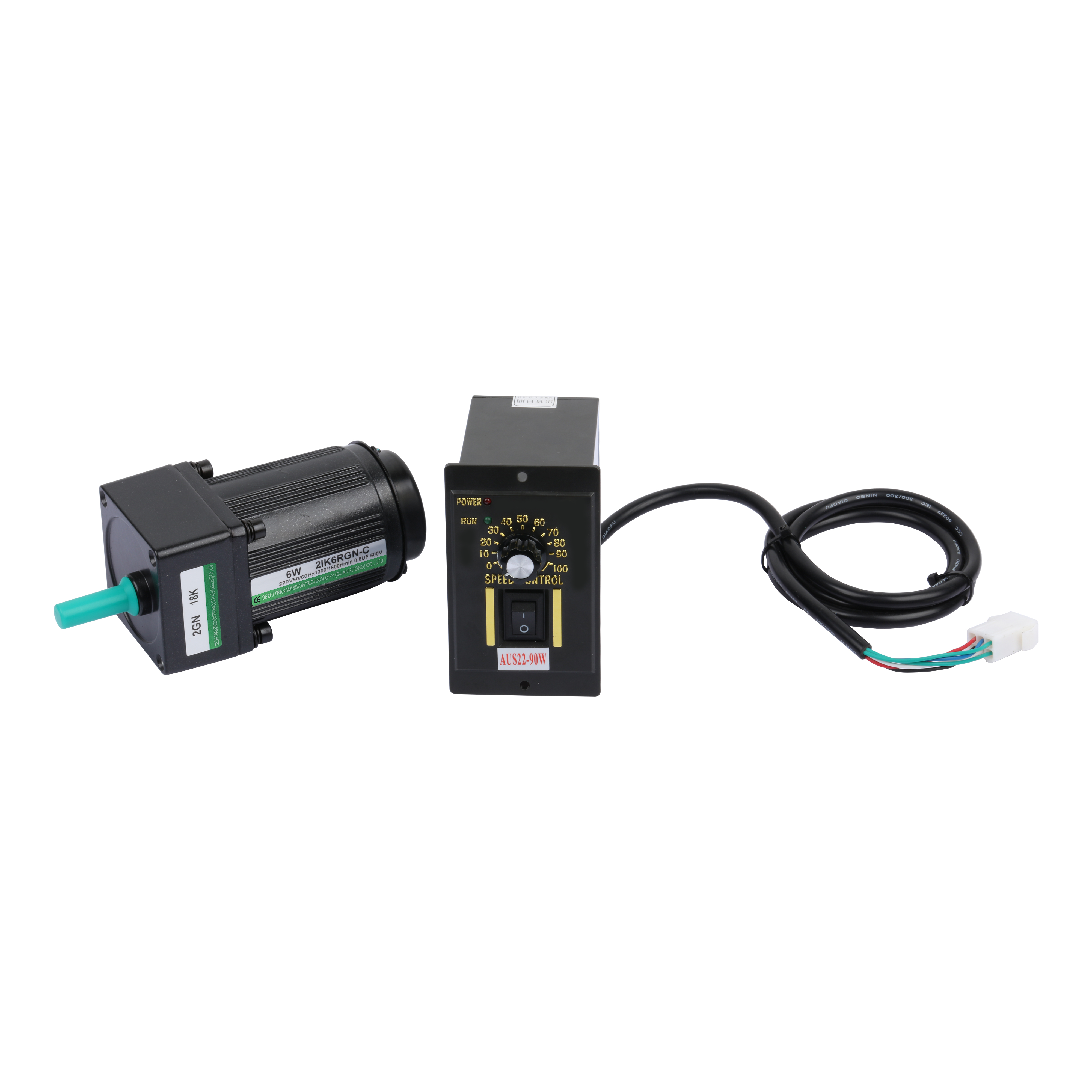

2020-12-21Speed control device

2021-01-13CGX060

2021-01-13CGF-042L1-8-P2

2020-12-21CGXZK042

2021-01-13Speed motor

2020-12-21Stepper motor

2020-12-21Stepper motor

2020-12-21Stepper motor

2020-12-21Gear reduction motor

2021-04-17Brake motor

2020-12-21Stepper motor

2020-12-21CGXZK142

2021-01-13CGH-090L1-10-P1

2020-12-21Stepper motor

2021-04-14Stepper motor

2021-04-14Planetary reducer

2021-04-15