Source:Industry News Release time:2022-07-23 Clicks: Popular:Reduction motor manufacturer

1. R series helical gear reduction motor

R series helical gear reduction motors have the characteristics of small size, light weight, high load-bearing capacity, high efficiency, long service life, easy installation, wide motor power range, fine transmission ratio classification, etc., and can be widely used in equipment that require deceleration in various industries.

2. S series helical gear worm motor

The helical gear worm reduction motor adopts the form of motor direct connection, and its structure is one-stage helical gear and one-stage worm gear transmission. There are six basic installation methods for output shaft installation. It can run in both forward and reverse directions. The helical gear adopts hard tooth surface, which ensures smooth operation and large load-bearing capacity. The working environment temperature is -10℃~40℃. Compared with similar products, this product has the characteristics of large speed range, compact structure and easy installation. It can be widely used in deceleration motors of metallurgy, mining, lifting, light industry, chemical industry, transportation, construction and other mechanical equipment.

3. K series bevel gear-helical gear reduction motor

The bevel gear-helical gear reduction motor adopts the motor direct connection form, and its structure is one-stage helical gear and one-stage worm gear transmission. There are six basic installation methods for output shaft installation. It can run in both forward and reverse directions. The helical gear adopts hard tooth surface, which ensures smooth operation and large load-bearing capacity. The working environment temperature is -10℃~40℃. Compared with similar products, this product has the characteristics of large speed range, compact structure and easy installation. It can be widely used in deceleration motors of metallurgy, mining, lifting, light industry, chemical industry, transportation, construction and other mechanical equipment.

4. F series parallel shaft reduction motor

The F series parallel shaft reduction motor adopts the modular design principle of unit structure, which greatly reduces the types and inventory of parts, and also greatly shortens the delivery cycle. Products are widely used in light industry, food, beer and beverages, chemical industry, escalators, automated warehousing equipment, construction, machinery, steel metallurgy, papermaking, artificial panel machinery, automobile manufacturing, tobacco machinery, water conservancy, printing and packaging, medicine, textiles, Building materials, logistics, feed machinery, environmental protection and other fields.

Recommended reading

Related Information

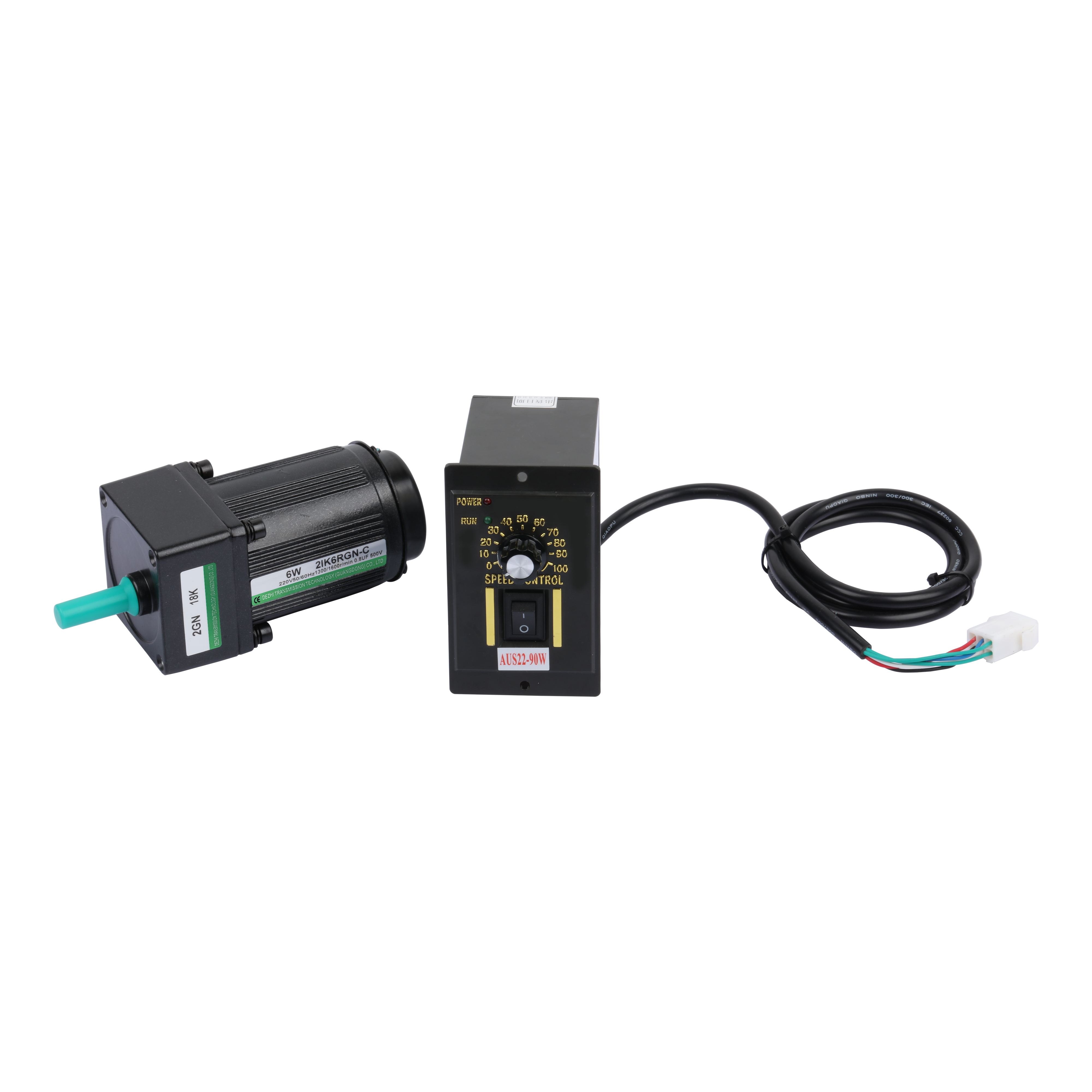

Small reduction motor

2020-12-21CGX115

2021-01-13CGXK060

2021-01-13Stepper motor

2020-12-21CGF-042L1-8-P2

2020-12-21Planetary reducer

2021-04-15Stepper motor

2021-04-14Stepper motor

2020-12-21CGZF-042L1-5-P2

2020-12-21Stepper motor

2020-12-21CGXK085

2021-01-13Planetary reducer

2021-04-15Three phase motor

2020-12-21CGXZK042

2021-01-13Planetary reducer

2021-04-15What is the purpose of a geared motor and how does it work?

2022-08-19How to deal with reduction motor noise?

2022-12-06A brief introduction to worm gear motors

2022-08-22Analysis of measurement methods for stepper motor speed changes

2022-07-14Reduction motor manufacturers introduce the product applications of reduction motors

2022-09-13Reducer usage conditions

2022-12-19What is the function and working principle of the reduction motor?

2022-08-09Introduction to stepper motor driver control chip types

2022-06-13Application advantages and characteristics of screw stepper motors

2022-07-19About the selection of stepper motor torque and speed

2022-06-11How to choose linear reduction motor?

2022-10-18Things to note when operating the servo reducer

2022-06-27Advantages and Disadvantages of DC Brushed Motors

2020-12-19Indicator terms for stepper motors

2022-03-08Applicable conditions for precision planetary reducer

2022-11-14